Remarks:

Basis of calculation of construction cost of aluminum formwork

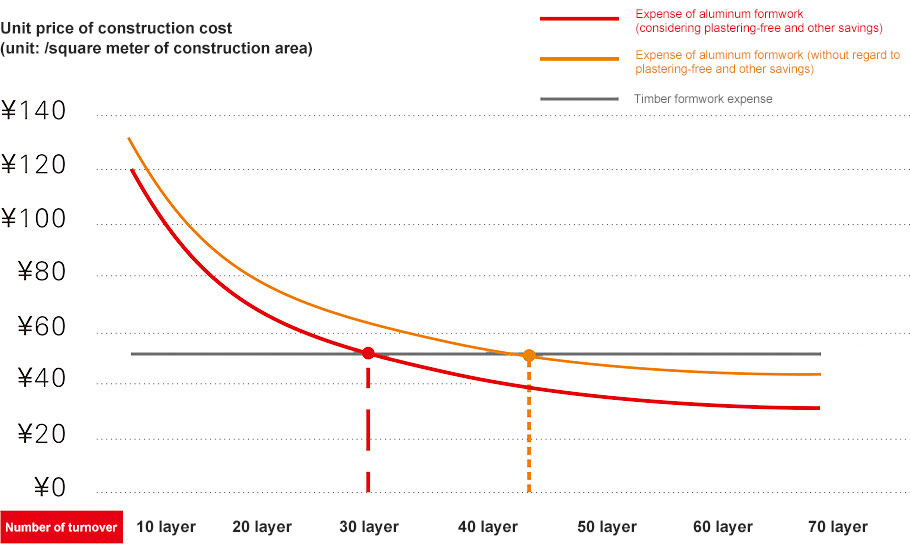

A:Unit price of aluminum formwork=1,400/m2 (including accessories, support, etc)

B:Recycling price of aluminum formwork=350/m2 (including accessories, support, etc)

C:Installation charge=29/m2 (including consumables)

D:Cost saving of plastering-free=9/m2 (already converted into the area of aluminum formwork)

E:Other expense saved=2/m2 (including: safety and civilized measures expenses, vertical transportation costs, site occupancy fees, garbage disposal fees)

Aluminum formwork construction cost =( A-B)/number of floor+ C-D-E

The construction cost of timber formwork is the cost of per square meter for contract for labor and materials. After construction is completed, all formworks will be taken as waste.

| Number of turnover | 10 layer | 20 layer | 30 layer | 40 layer | 50 layer | 60 layer | 70 layer |

|---|---|---|---|---|---|---|---|

| Timber Formwork | 52 | 52 | 52 | 52 | 52 | 52 | 52 |

| Aluminum Formwork | 123 | 71 | 53 | 44 | 39 | 36 | 33 |

| Aluminum Formwork | 132 | 80 | 62 | 53 | 48 | 45 | 42 |

| Timber Formwork | Steel Formwork | Plastic Formwork | Aluminum Formwork | |

|---|---|---|---|---|

| Advantages | Light, cheap, without restrictions to number of formworks, can be processed as required. | High strength and large number of turnover. | Smooth surface, non-hygroscopic, anti-mildew, acid and alkali-resisting, not easy to crack, quite lower cost compared with steel formwork. | Light, large number of turnovers, high carrying capacity, wide scope of applications, convenient construction, and recovery value tends to be high. |

| Disadvantages | Less frequently used, a certain amount of wastage generated during the course of processing, large resource consumption. | Heavy, inconvenient to use, corrode and higher cost. | Low strength and stiffness, relatively large coefficient of thermal expansion, quite recyclable, polluting the environment. | Must be used in buildings with relatively more standard floors, field installation. |